|

|

|

|

|

|

|

|

|

|

These

pictures display the interior after

disassembly. Notice the waffle pattern floor

insulation in the picture above. This insulation is

factory correct and was installed as a insulation

or sound deadening material. The above photos

also display the interior floor boards and their

exceptional and original condition. |

|

|

|

|

|

|

|

If you

look closely at these pictures to the left,

right and below, you will see traces of satin black

paint

sprayed on the seat pedestals and around the

rear shelf area. The factory did this to hide the

body color in the cockpit. |

|

|

|

|

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

|

|

|

|

|

|

|

The above

row displays pictures

of the dash disassembly.

All switches, knobs, lever and connections

are documented and checked for serviceability. |

_small.JPG) |

We

disassemble the dash and

replace all heater temperature sliders

along with properly lubricate all cables

and connectors. |

_small.JPG) |

With the

dash board apart and all

other misc. trim, we can further inspect

all areas of the rebuild.

You can also see the

satin black brushed

on around speaker grill and etc... |

_small.JPG) |

|

|

|

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

These

pictures above highlight the protection

level the factory set in place long ago. |

After

removing the plastic liner to the door panel,

we have a more accessible view to all

working mechanisms for further inspection. |

Above: Notice

the plastic liner that was glued on

from factory to limit the outside elements

from entering the cabin. |

_small.JPG) |

_small.JPG) |

_small.JPG) |

A close

up view at the masking tape that

Mercedes Benz used for

that extra layer of protection. |

Mercedes used this material to safeguard the paint.

Adding to the tradition of engineering

to only the finest standards.

|

From behind the front chrome grill

to the backside

of the door panel chrome trim. |

|

We

document the placement and extent

of this material. We then duplicate it to reflect

the standards all Pagodas were born to. |

|

The

pictures below highlight the interior details,

and how they all come together to match up.

|

From the

backside of door panels,

to kick panels and glove box undersides.

All interior panels match. |

Below is

a close up at the backsides

of the door panels. |

|

_small.JPG) |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

_small.JPG) |

_small.JPG) |

| |

|

|

|

|

_small.JPG) |

| |

|

|

|

_small.JPG) |

|

The

pictures below shows just how much

caulking the factory used to finish assembly

of the hard tops. |

The color code was marked with grease

pencil under the rear shelf covering.

|

The body

number is visible

on the bottom side of the hard top. |

|

_small.JPG) |

_small.JPG) |

| |

|

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

_small.JPG) |

_small.JPG) |

_small.JPG) |

The factory applied caulking to every step as they assembled the hard

top. From under all the chrome, to in between the

channel guides. We carefully heat up and remove all the caulking along

with the chrome from the hard top.

|

|

|

|

The factory painted the

backside of the chrome bumpers. Here we see the paint color is a light

beige.

This process helped with corrosion prevention.

|

| |

|

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

The detailed pictures above

and below are of some chrome interior parts.

The fresh air vents and flaps are completely disassembled and re-plated.

The velvet lining on the backside of some interior trim is cleaned and

reapplied to protect the

new interior dash panels. |

_small.JPG) |

_small.JPG) |

_small.JPG) |

The fresh

air vents before

disassembly. |

A close

up picture of the fresh air

vent units from the backside. |

The ashtray chrome bezel is

attached

with three small tabs. Our advise is to gently

heat up the tabs when

disassembling the ashtray.

|

|

|

|

A close up picture of the fresh air vent and flaps before the re-plating

process. Notice the small round tabs on

the ends of the vent flaps. Any chrome build up must be filed down to

fit back into the holder.

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

| |

|

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

Pictures of the new oil

pump, new cylinder head, and new pistons.

We double check all clearances and surfaces before mating the

cylinder head to the block.

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

| |

|

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

| |

New gears, new intake and

exhaust valves

and rotocaps. |

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

| |

|

|

|

|

|

Above are some pictures of the engine before we disassembled and started

the full rebuild.

Below are all the pictures during the engine rebuilding process.

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

| |

|

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

| |

|

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

| |

|

|

_small.JPG) |

_small.JPG) |

_small.JPG) |

| |

|

|

|

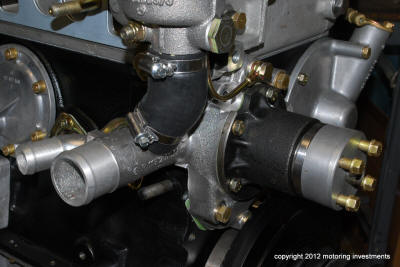

The right and left pictures

shown

of the fuel injectors, before and after. |

|

|

The water pump and side

plates,

before and after. |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

_small.JPG) |

|

|

| |

|

|

|

|

Before

|

After |

|

|

| |

|

|

|

|

|

Here are pictures of the body during the paint process.

|

|

The

pictures of the 280SL with

new paint.

|

|

| |

|

|

|

|

|

The pictures shown above and

below show us the seats during restoration,

using new Mercedes pads.

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

The above picture shows us

the new headliner and new foam being installed. All the leather is

trimmed and

the backsides are skived to fit the panels together correctly.

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

The new door panels

are fitted to the doors. |

|

| |

|

|

|

The tail lights lenses and

bezels

are replaced with new lenses and re-plated

bezels. The new lenses are exact

duplicates of the originals. |

|

| |

|

|

|

The European headlamps are

being fitted with

all the correct bulbs. |

|

| |

|

|

|

|

|

The pictures above and below

show us the headliner and hard top assembly. Along with the new foam,

weather seals,

headliner and re-plating all the chrome,

we replaced every screw with new hardware. The pictures below

show of how flush all the new hardware sets into the channel.

|

|

|

|

| |

|

|

|

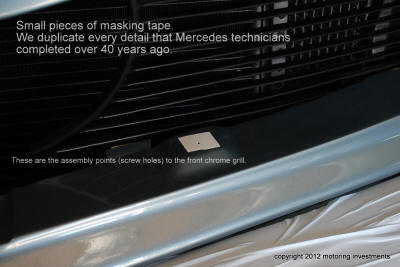

The pictures to the left and

right

display the cloth tape applied to the

front of the bug grills to mate up with the body.

We duplicate every detail that Mercedes

factory technicians completed over

40 years ago.

|

|

| |

|

|

|

|

|

These pictures are of the

fresh air vents flaps, bezels and

all interior parts back from re-plating and ready for reassembly.

|

|

|

|

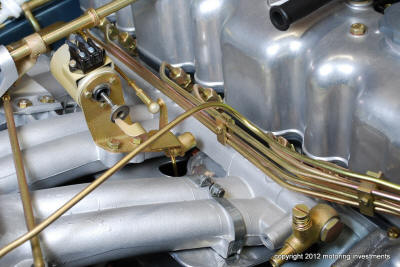

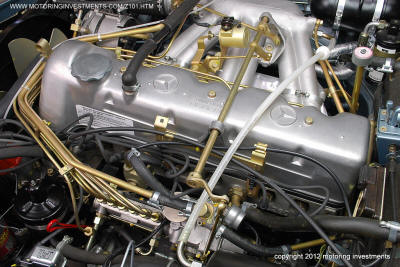

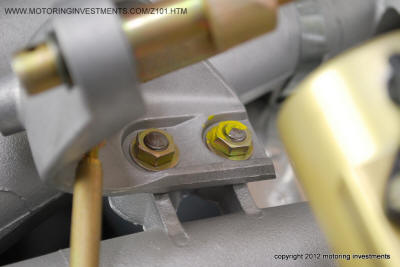

Below are the final engine

bay pictures with all the

correct clamps and accessories as well as the painted dotology in place. |

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

The picture above displays

the

N.O.S ( new old stock )

hood limiting strap in the correct color. |

|

|

|

|

| |

|

|

|

|

|

The spot welds along the

inner fenders and painted inner fender plugs.

|

|

|

|

| |

|

|

|

|

|

| |

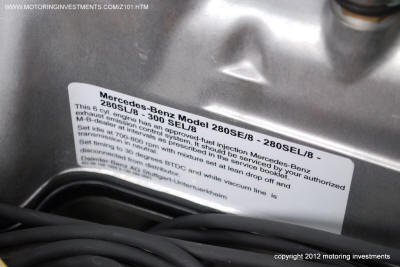

Early 280SL models were equipped with a label

on the transmission dip stick. Later

models have an embossed (Bakelite)

lid with no label.

|

|

|

|

|

The pictures above and below

display all the details we add to complete the engine bay.

The dotology marks at the factory indicated locations, new decals and

labels that

finalize the look.

|

|

|

|

| Valve

cover label |

Brake booster label |

shock

tower dotology |

|

The picture to the left

shows the

wiper motor base and motor in new condition.

We remove the base plates to

the wiper motor

and have them re-plated to factory standards.

|

|

| |

|

|

|

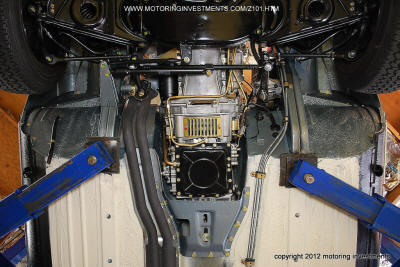

Below are the final

undercarriage pictures. |

|

| Before |

|

After |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

The above photos show us the

dotology markers we duplicate through out the undercarriage.

|

|

|

|

| |

The picture above displays the white paint behind

the bumpers. We duplicate every detail in our

restorations. The factor did this to protect the

from the elements.

|

|

|

|

|

The

picture above is of the transmission

mounting plate body number. |

A close up shows up the # 205.

This number coincides with the last

sequence of numbers on the last line,

pictured below.

|

The

picture below shows the

new transmission I.D. plate in place

with the correct rivets. |

|

|

|

The last of the dotology

spots are applied to the undercarriage.

|

|

|

|

| |

|

|

|

|

|

The pictures above show the process of installing the windshield. To

facilitate the install of the windshield and trim,

install the drivers side wooden bow at the topside of dash, first. Then

the windshield and surrounding trim.

This will help fit all other related parts and panels perfectly.

|

|

|

|

The photo above is with the European

lights activated in the fog light position.

|

|

The photo

above is with the European

lights activated in the running light position. |

|

|

|

| |

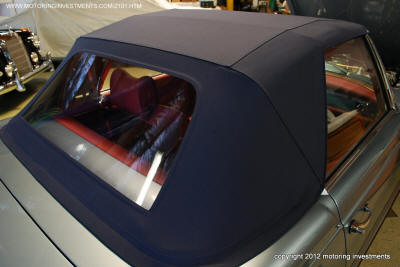

The pictures below display

the canvas top

and frame in the final steps of restoration.

New tensioning cable, foam, straps,

and new vinyl.

|

|

|

|

|

| |

The new vinyl is glued down

firmly and

fitted to perfection.

|

|

|

|

|

| |

|

|

|

|

|

Applying the right type of glue to the outside of the canvas top for

the new moss rubber strips is crucial

for a lasting hold.

|

|

The canvas top frame has

been reconditioned

with new vinyl at the header bar, new nylon

straps that affix the bows together, new foam

and all new weather seals. |

|

| |

|

|

|

|

|

After the new canvas top is

installed, the protective rear window material and waxy tissue paper is

removed.

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

The pictures above and below

display the bug grills as well as the

small pieces of masking tape we apply

to the assembly points at the front grill. |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

The pictures below display

the

chrome grill in its flawless condition.

From fitting the grill before re-plating and

during the painting process to installation

of the buffer tape, we overlook no detail.

|

|

| |

|

|

|

|

|

The pictures below show us the final look of the canvas soft top. We

carefully remove the

waxy protective coating on the rear window.

|

|

|

|

| |

|

|

|

The hubcaps are painted

using the

same techniques that the factory technicians

used in the day; even down to

the use of the factory

hubcap stencil.

|

|

| |

|

|

|

The new hubcaps are

installed using

the correct yellow cadmium plated clips.

|

|

| |

|

|

|

|

|

|

Mercedes stencil still "in box". |

|

|

|

|

|

The dotology on the

spare wheel is

applied from the technicians after they have

inspected the wheels. |

|

|

|

|

| Date

coded wheels match the car |

The Firestone Phoenix

is the original spare tire. |

The curb lip, was to limit

the curb rash and

protect the whitewall scuffs.

|

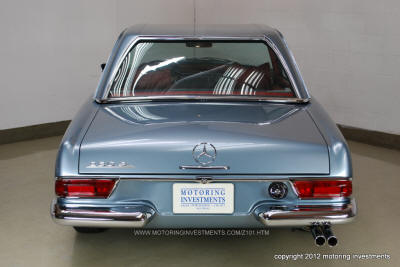

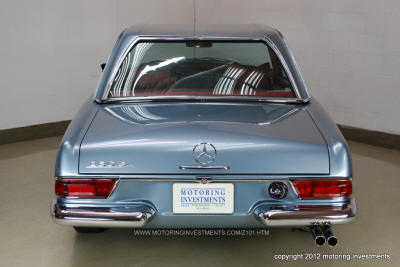

The photos below are of the

final stage. The restoration build is completed with a fully

documented portfolio, along with the final photos of the car. |

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

The pictures above and below show the restored

folding top storage compartment. The new

decal in place, shows care tips

and instructions on

lifting and storing the folding top.

|

|

|

|

|

| |

|

|

|

|

|

| |

The screw that affixes the fresh air housing

to the body must also be gold cadmium plated.

|

|

|

|

|

| |

|

|

|

|

|

| |

The pictures above left &

right

are close ups of the

headlamp notches. |

|

|

|

|

The picture below displays a

close up view of

the chrome trim and rubber profile

that is between them.

Early cars have no rubber profile that fits

behind the chrome trim. |

|

|

|

| |

|

|

|

|

|

| |

The trunk is finalized with

the appropriate "early SL" tire pressure label

and the tire change instruction card.

|

|

|

|

|

| |

Mercedes Benz changed over from the

early tire pressure label after late 1969.

|

|

|

|

| |

|

|

|

The photos below show the

car and its final state...

PERFECTION. |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

A Nardi

Steering wheel finishes the

elegant look. |

New sun visors |

|

|

|

|

| |

The photo above shows the

hazard knob.

We replaced the knob with one from our

N.O.S. ( New Old Stock) inventory to

complete the dash. |

|

|

The photos to the left and

right

display the show quality paint work

performed. We complete the cars to have

a factory correct look.

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

Before |

Before |

|

|

|

After |

After |

|

|

|

| |

Before |

|

|

|

|

| |

After |

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

Before |

After |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|