|

|

| |

|

|

| |

|

|

| |

|

|

|

|

| |

|

|

|

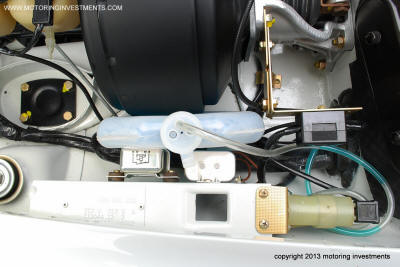

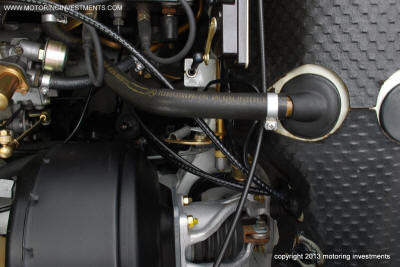

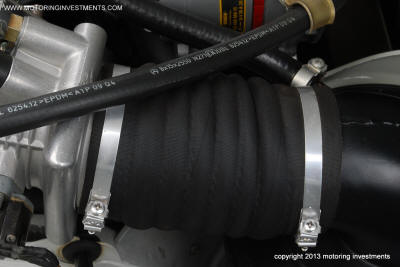

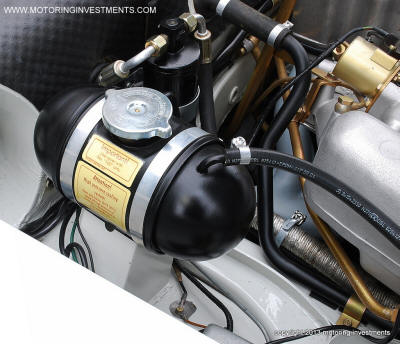

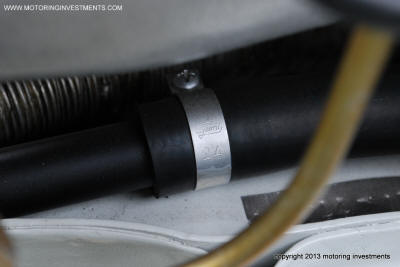

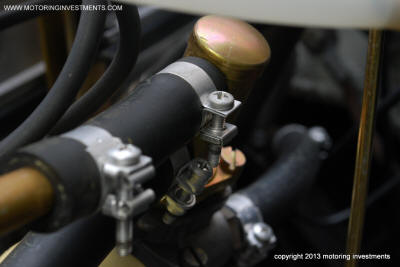

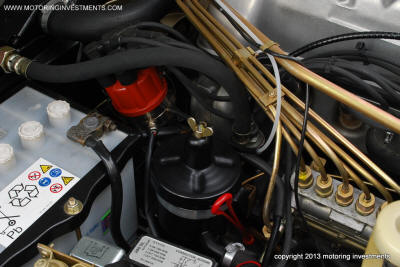

These

pictures shown above and below, are to display the cars' originality. A

very low mileage car is showing

all the original and correct clamps. |

|

|

| At power

steering reservoir |

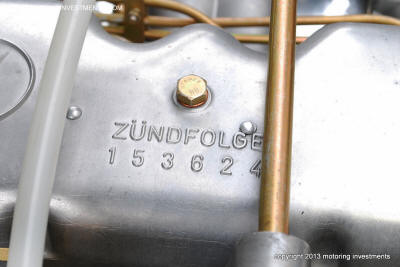

Topside of

valve cover. |

|

|

We will

duplicate all the original dotology

shown through out the engine bay. |

At the

firewall to the heater

core, clamps are correct. |

|

|

| |

At air filter

canister |

|

|

The pictures

above are battery area. We removed the battery and tray to show the

corrosion that

often happens here. |

|

|

| |

|

|

|

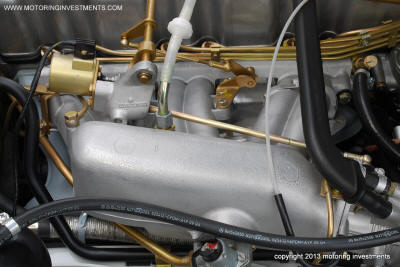

As the engine

bay is disassembled, we carefully catalogue and

document every aspect of the build. |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

Notice the correct bolts towards the inside of

the thermostat housing. Slotted bolts facilitate

service and often times not present after

decades of service.

|

The engine

bay disassembly

is meticulously documented.

The photo below shows the distributor and

the need for servicing. |

| |

|

|

|

|

|

|

|

|

| |

|

|

|

| |

|

|

|

The motor is

pulled from its bay, disassembled and documented. All o-rings, seals,

plates and

plugs will be replaced. Every aspect of the engine and surrounding

components is inspected. |

|

|

|

|

|

|

|

|

|

|

The picture

above shows us the difference

between old and new engine mounts. |

The old

mount, pictured above left, is original

to the low mileage Pagoda. |

|

|

| The engine

bay parts are next in line for refinishing. |

After

prepping and refinishing,

the parts look as new. |

|

|

All the fasteners, brackets, clamps, fuel lines and plates are sent off

to

be re-plated. The gold and silver cadmium pieces

are catalogued and upon plating completion, the pieces are

sorted. Scroll down on the page to view

the newly plated hardware and components going into the engine bay.

|

|

|

| |

|

|

|

| |

|

|

|

|

Before |

After |

The intake manifold, valve cover and other parts

have been de-burred and

tumbled with a ceramic

media to achieve the correct finish.

|

|

|

| Before |

After |

|

|

| Before |

After |

|

|

| |

|

|

|

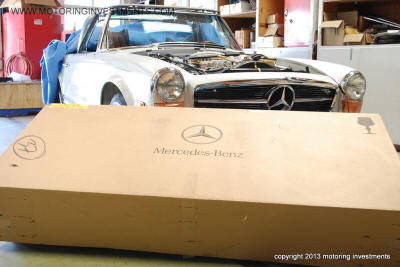

The fuel tank

has been replaced with a NEW OEM Mercedes Benz tank.

Notice the pads on the topside?

These are to protect from vibrations as well as adding cushion against

the trunk floor. |

|

|

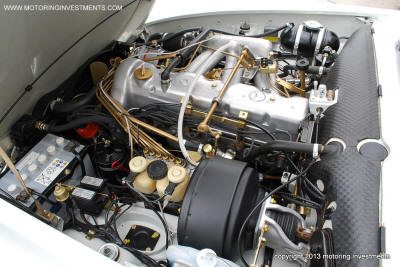

The photos

below show the engine bay after being refinished. The gold cadmium

plated

parts are now ready to be installed. |

|

|

| |

|

|

|

| |

|

|

|

The photo below highlights the

panels just behind the bug grills. These panels

are

to be "brush" painted

to duplicate the Mercedes Benz factory look.

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The owner of this car was so impressed with the progression of the

engine bay

restoration, that he commissioned our shop to restore and recondition

the underside of the car as well.

Scroll down to see pictures of the undercarriage and progress.

|

|

|

The pictures above show the front end with

the sway bar back in place and its hardware. Notice the wheel wells

from underneath? Below are pictures of the wheel well refinishing

process. |

|

|

Above and below we see the pictures

BEFORE the restoration. |

Shown here are the wheel wells

AFTER. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The rear end parts are powder coated to

endure the road elements. |

|

|

|

The rear end is now back into place and

shown above. |

|

|

The

protective plastic liner under the door panel is still in place. This is

carefully removed and placed back into position as the

doors will be serviced for any rattles and loose window guides or

blocks. The number on the backside of the door panel

is also shown below. This number

is found on many interior panels, it

is called the production number. |

|

|

|

|

|

|

|

The car has the original carpet and

interior. Although 40 plus years of use did scuff up the

door threshold trims. We carefully remove the old trims from the

original carpet. We then remove and re-glue all the correct

spacer washers to the backside of the threshold trims and install back

into car. |

_small.JPG) |

|

|

These pictures below highlight the finished

threshold trims. |

|

|

The trunk is

corrosion free but does need to be re-finished.

The tar pads must not to be painted over. These secure the

fuel sending units' wiring to the trunk floor. |

|

|

| Above are the

before pictures. Below, the after pictures are

displayed, highlighting the correct satin black finish. |

|

|

| |

|

|

|

The pictures

above are of the car being disassembled to refinish the right rear

corner.

The images below are of the corner, close-up. |

|

|

| The images

below display the right rear corner after we refinished in our body

shop. |

|

|

| |

|

|

|

| |

|

|

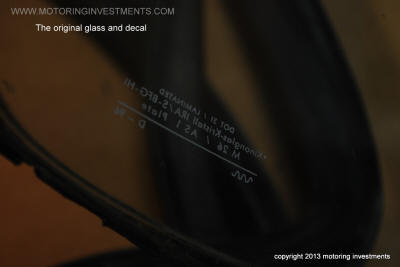

The original

windshield, although in great condition from cracks and chips, is

delaminating.

Below, are pictures of the car receiving a new OEM windshield and new

seal. |

|

|

| |

|

|

|

| |

|

|

|

|

| |

|

|

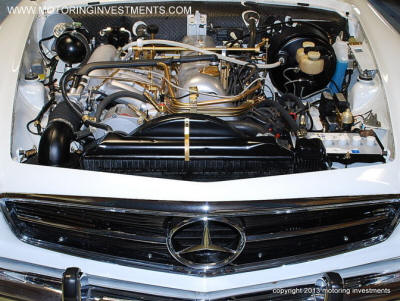

| The engine

bay is now completed and shown in the pictures below. |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

| The engine

bay images in the finished stage. |

|

|

| |

|

|

|

|

The picture

above is the hood gap before the

adjustments. |

The image

above and to the right are after

the necessary hood adjustments. |

Hood

clearance is perfect. |

|

|

| |

|

|